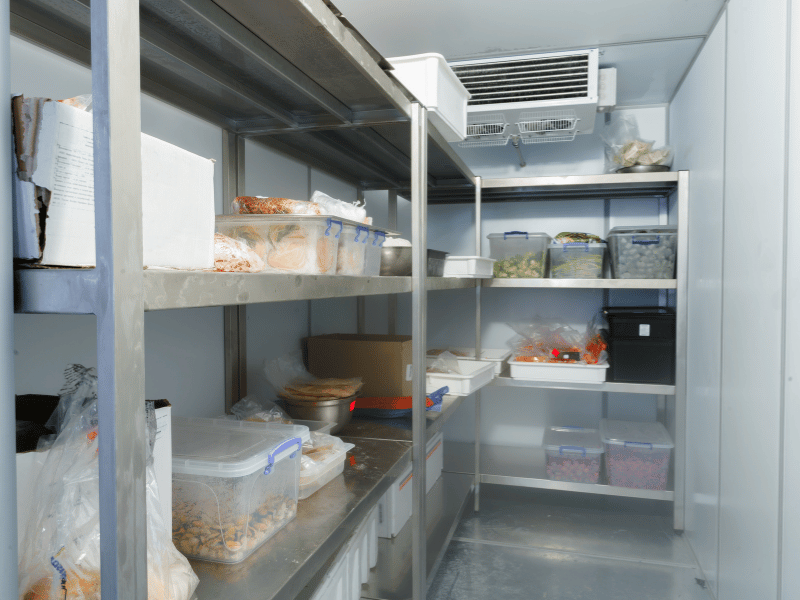

Commercial kitchen equipment service, repair and installation company Joe Warren & Sons discusses the importance of maintenance plans for refrigeration units

In the fast-paced world of the food service industry, commercial refrigeration equipment is one of the most critical components to keep operations running smoothly. However, like any complex system, refrigeration units are prone to wear and tear over time. The best way to ensure your equipment remains reliable, efficient, and long-lasting is through planned maintenance. At Joe Warren & Sons, we’ve seen how regular maintenance can prevent costly breakdowns and extend the lifespan of refrigeration systems. Here’s why having a preventive maintenance plan is essential for your business.

1. Prevent Costly Breakdowns

Unexpected refrigeration failures can have devastating effects on food service operations. Not only do these breakdowns result in expensive emergency repairs, but they can also lead to product spoilage and lost revenue. Planned maintenance helps detect small issues before they escalate into major problems.

The Benefit:

Routine inspections and maintenance tasks, such as cleaning condenser coils, checking refrigerant levels, and inspecting components, can catch potential malfunctions early. This proactive approach minimizes downtime and avoids the financial impact of emergency service calls.

2. Maximize Energy Efficiency

Commercial refrigeration systems that aren’t properly maintained can become inefficient over time. Dust, debris, and worn-out components cause refrigeration units to work harder, consuming more energy than necessary. This increased energy usage not only leads to higher utility bills but also reduces the overall efficiency of the equipment.

The Benefit:

A well-maintained refrigeration unit operates at peak efficiency, which reduces energy consumption and helps lower operational costs. Regular maintenance ensures that the unit runs smoothly, with clean coils, well-lubricated parts, and proper refrigerant levels, allowing it to perform optimally.

3. Extend the Lifespan of Your Equipment

Commercial refrigeration systems are a significant investment, and the last thing a business wants is to replace expensive equipment prematurely. Planned maintenance helps extend the lifespan of your refrigeration units by keeping them in good working condition for longer periods.

The Benefit:

By addressing minor issues before they cause irreparable damage, maintenance plans can prolong the life of your refrigeration equipment. Regular upkeep reduces strain on essential components, preventing wear and tear that can lead to early failure. This ultimately saves money by delaying the need for costly replacements.

4. Ensure Food Safety and Compliance

Maintaining safe and consistent temperatures is critical for food safety. Malfunctioning refrigeration units can result in temperature fluctuations that compromise food quality, leading to foodborne illnesses and health code violations. A comprehensive preventive maintenance plan ensures that your refrigeration systems consistently operate within the required temperature ranges.

The Benefit:

By ensuring that your refrigeration equipment functions properly, you’re not only protecting your food products but also maintaining compliance with food safety regulations. Regular temperature checks, calibration of thermostats, and routine cleaning reduce the risk of spoilage and health hazards.

5. Reduce Emergency Service Calls

While emergency service calls are sometimes inevitable, they can be greatly reduced with preventive maintenance. A maintenance plan involves regular inspections that identify issues before they result in equipment failure. This allows business owners to schedule repairs at convenient times rather than dealing with unexpected emergencies.

The Benefit:

Planned maintenance minimizes the frequency of emergency service calls, saving both time and money. Instead of dealing with disruptive equipment failures, businesses can schedule repairs during off-peak hours, ensuring that operations continue without interruption.

6. Maintain Optimal Performance During Peak Times

For food service businesses, peak times such as holidays, special events, and seasonal rushes are critical to overall profitability. Equipment failures during these times can lead to significant losses. Planned maintenance ensures that your refrigeration equipment is fully prepared to handle the demands of high-volume usage.

The Benefit:

Regularly scheduled maintenance before peak periods guarantees that your refrigeration system is in top condition when you need it most. This preparedness reduces the risk of breakdowns during crucial business hours, ensuring smooth operations and consistent service.

Conclusion

Planned maintenance for commercial refrigeration equipment is essential to keeping your business running smoothly and efficiently. At Joe Warren & Sons, we understand the importance of reliable refrigeration systems in the food service industry. Our planned maintenance plans are designed to prevent breakdowns, maximize energy efficiency, extend the lifespan of your equipment, and ensure food safety. By investing in routine maintenance, you can avoid costly repairs, reduce emergency service calls, and maintain optimal performance during your busiest times.

If you’re ready to protect your refrigeration systems and secure the long-term success of your business, contact Joe Warren & Sons today to learn more about our comprehensive preventive maintenance services.