In the food service world, refrigeration equipment is vital, not only for food safety but also for operational efficiency. Yet, despite the importance of keeping these units in top shape, there are numerous misconceptions about how they should be maintained and operated. At Joe Warren & Sons, we’ve seen how falling for these myths can lead to costly mistakes, so let’s debunk some of the most common refrigeration misconceptions and set the record straight.

Myth 1: Turning Refrigeration Units Off Saves Energy

One of the most pervasive myths is that turning refrigeration units off during slower periods can save energy. In reality, frequently powering a unit on and off creates greater energy demand, as the unit has to work harder to return to and maintain a stable, low temperature. Furthermore, repeatedly turning a unit on and off strains its compressor, potentially leading to early wear and tear.

The Truth: Continuous operation at a consistent temperature is more energy-efficient and extends the lifespan of the equipment. Instead of turning units off, consider routine cleaning and maintenance to improve efficiency.

Myth 2: All Refrigeration Units Work the Same Way

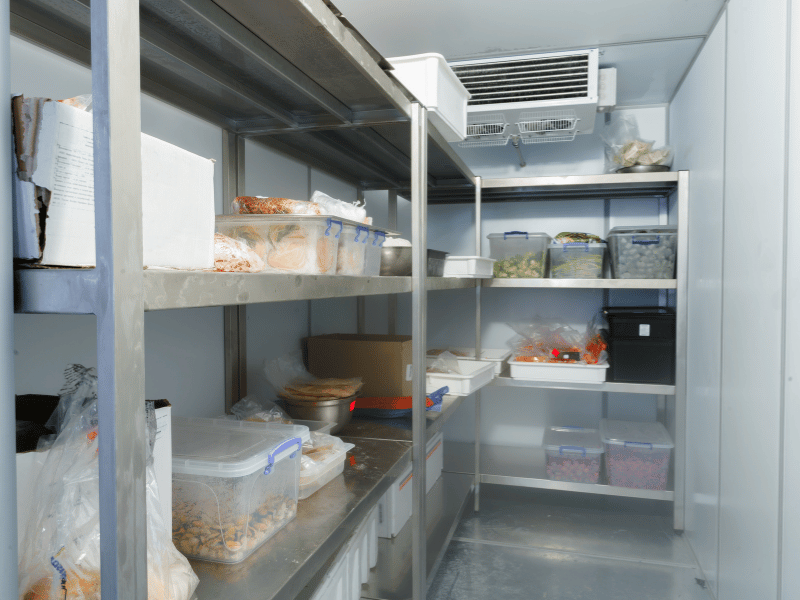

Not all refrigeration units are created equal. Walk-in coolers, reach-in refrigerators, and blast chillers are each designed with specific purposes in mind, and each has unique maintenance needs. For instance, a blast chiller is meant to rapidly bring down the temperature of hot items, while a walk-in cooler is designed for consistent, bulk storage.

The Truth: Understanding the differences and using each unit according to its purpose helps maintain optimal performance. Misusing a refrigeration unit can cause temperature inconsistencies and even safety issues with stored food.

Myth 3: The Colder, the Better

Some operators think setting their refrigeration units to the lowest possible temperature will keep food fresher. However, this practice can actually cause issues, especially if the set temperature is lower than recommended for the type of food being stored. Freezing items that should be chilled, for example, can damage quality and alter taste, affecting the customer experience.

The Truth: Following manufacturer-recommended temperature settings (e.g., around 35-38°F for refrigeration and -10°F for freezer units) ensures food stays safe and maintains its intended quality.

Myth 4: Routine Cleaning Isn’t Necessary for Sealed Units

Many people think that since commercial refrigeration units are sealed, they don’t require frequent cleaning. However, even though food and contaminants may not directly enter a sealed refrigeration system, dust, grease, and other particles can accumulate on parts like the condenser coils, affecting performance and energy efficiency.

The Truth: Cleaning coils, fans, and filters regularly prevents unnecessary strain on the equipment. A well-maintained unit operates more efficiently and with less energy, ultimately saving money and extending the unit’s life.

Myth 5: Using Household Cleaning Products is Fine for Refrigeration Units

Household cleaning products are commonly used for a variety of tasks, so it’s easy to assume they’re safe for commercial refrigeration units too. However, some chemicals found in standard cleaners can be too harsh for commercial units, corroding surfaces or leaving residues that might contaminate food.

The Truth: Using products specifically designed for commercial kitchen equipment is key. These cleaners are formulated to be safe for use in food environments and are effective at removing grease and grime without damaging surfaces.

Myth 6: Bigger Refrigeration Units Mean Better Performance

The idea that bigger is better doesn’t necessarily apply to commercial refrigeration. A larger unit that is half-empty may consume unnecessary energy to keep unused space cold, leading to higher utility bills without any added benefit.

The Truth: Select refrigeration units based on your establishment’s actual storage needs. A right-sized unit, paired with energy-efficient practices, is a better investment than a larger one that takes up unnecessary space and energy.

Myth 7: Quick Repairs Are Enough to Maintain Equipment

Many businesses resort to quick fixes when an issue arises, thinking that as long as the unit is running, everything is fine. But temporary fixes may only address surface problems, leaving underlying issues to worsen over time, ultimately leading to breakdowns at the worst times.

The Truth: Routine preventive maintenance by trained professionals ensures that any issues are spotted early and properly repaired. Investing in regular maintenance also reduces the risk of emergency breakdowns and the resulting disruptions to operations.

Understanding how commercial refrigeration truly works—and busting these myths—is crucial for maintaining efficient, long-lasting equipment in your kitchen. At Joe Warren & Sons, we offer expert consultation, maintenance, and repair services tailored to your specific refrigeration needs. Our team is here to ensure your equipment operates smoothly, helping you save on energy, maintain food safety, and extend the life of your units.

Contact us today to learn more about our preventive maintenance programs and keep your kitchen running at peak performance, year-round.