In a bustling restaurant kitchen, the performance of your commercial equipment is critical. While regular maintenance is essential, your staff plays a crucial role in keeping your equipment running smoothly. Empowering employees to identify potential issues early can save you from costly repairs, downtime, and disruptions to service.

Here are practical tips to train your team to be your first line of defense against equipment breakdowns.

1. Start with the Basics: Equipment Orientation

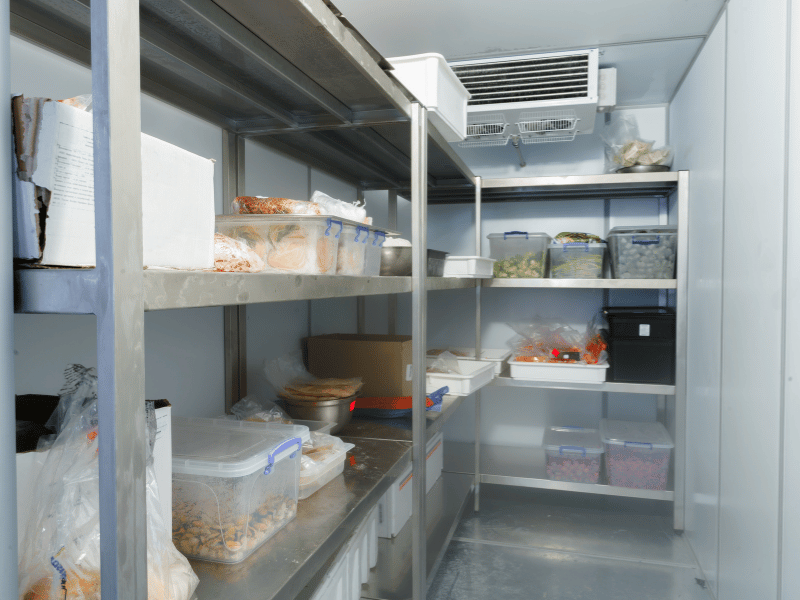

When onboarding new employees, include a thorough orientation on your kitchen equipment. Teach them how each piece works, its normal operating sounds, and common signs of trouble. For example, a walk-in cooler should maintain consistent temperatures and operate without unusual noises or frost buildup.

2. Create a Simple Checklist

Provide your staff with a daily or weekly equipment checklist. Include tasks like:

- Checking for leaks under refrigeration units.

- Listening for unusual sounds from ovens, fryers, or dishwashers.

- Inspecting seals and gaskets for wear and tear.

- Noting any unusual odors or excessive heat around equipment.

Encourage your team to report anything that deviates from the norm immediately.

3. Teach Temperature Monitoring

Ensure that employees know how to check and record equipment temperatures regularly, especially for refrigeration units. Train them to recognize red flags, such as fluctuating temperatures or units struggling to maintain the correct range. Early detection can prevent food spoilage and maintain compliance with health regulations.

4. Emphasize the Importance of Cleaning

A clean machine is a healthy machine. Show your staff how to clean equipment properly. Poor cleaning practices can lead to buildup, which affects performance and can cause malfunctions.

5. Role-Play Common Scenarios

Set up role-playing sessions where employees can practice identifying and responding to potential issues. For instance:

- Simulate a noisy refrigerator fan and ask what actions should be taken.

- Show a fryer that takes longer than usual to heat and discuss the possible causes.

This hands-on approach makes training engaging and memorable.

6. Encourage Open Communication

Foster a culture where staff feel comfortable reporting issues without fear of blame. Make it clear that early reporting is valued and crucial to keeping the kitchen running efficiently.

7. Provide Quick-Reference Guides

Place laminated quick-reference guides near equipment with tips on spotting common problems. For example:

- “Listen for rattling or humming—this could indicate a compressor issue.”

- “If ice forms on coils, call for maintenance immediately.

These guides serve as helpful reminders during busy shifts.

8. Partner with Trusted Experts

Reassure your staff that they’re not alone in addressing equipment issues. Partnering with Joe Warren & Sons ensures you have reliable professionals on call for regular maintenance and emergency repairs. Let your team know they can depend on our experts for guidance and support when something feels off.

Invest in Early Detection

Training your team to spot equipment problems early is an investment in your kitchen’s efficiency and your business’s bottom line. By empowering your staff with knowledge and tools, you can prevent small issues from becoming major disruptions.

Ready to keep your kitchen running at peak performance? Contact Joe Warren & Sons today for expert advice and service plans tailored to your needs. Let’s work together to make equipment downtime a thing of the past!