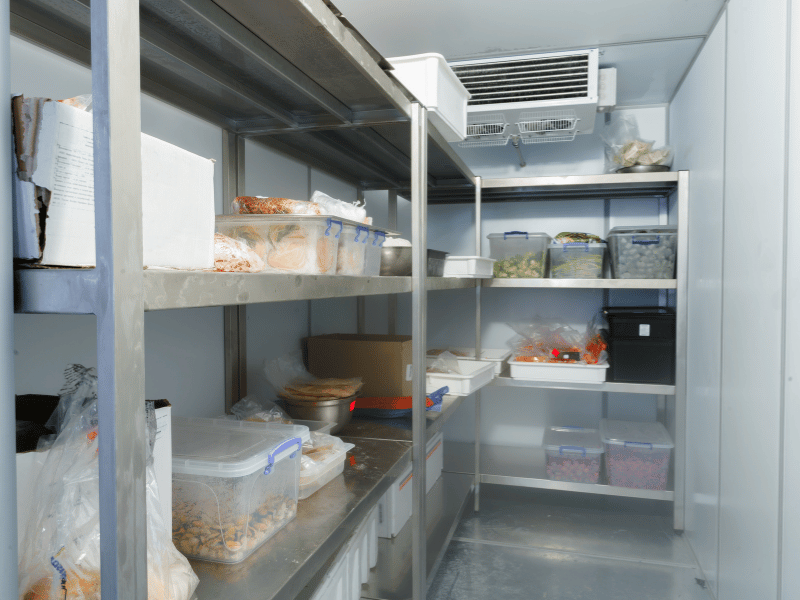

Ice machines are indispensable in restaurants and foodservice establishments, ensuring a steady supply of ice for beverages, food preservation, and various culinary needs. However, like any other piece of equipment, ice machines require regular maintenance to function efficiently and reliably. Without proper care, ice machines can become breeding grounds for bacteria, leading to health risks and operational downtime. Here’s a comprehensive checklist to help you maintain your ice machine and keep it running smoothly.

1. Daily Maintenance

a. Clean and Sanitize

Wipe down the exterior of the ice machine daily using a damp cloth with a mild detergent. Focus on areas that come into frequent contact with staff, such as handles and dispensers. This simple step helps prevent the accumulation of dirt and germs.

b. Inspect for Leaks

Check for any visible leaks around the machine. Leaks can indicate issues with the water supply or drainage system and should be addressed immediately to prevent water damage and ensure the machine operates correctly.

2. Weekly Maintenance

a. Empty the Ice Bin

Once a week, empty the ice bin completely and allow it to air dry. This prevents the buildup of moisture, which can lead to mold and mildew growth. Additionally, inspect the bin for any signs of mold or dirt and clean it thoroughly.

b. Check the Water Filter

Inspect the water filter for any signs of clogging or contamination. A clogged filter can restrict water flow, reducing the efficiency of the ice machine and affecting the quality of the ice. Contact your service professional to replace the filter if necessary, following the manufacturer’s recommendations.

3. Monthly Maintenance

a. Deep Clean the Interior

Contact your service professional to perform a deep clean of the machine’s interior components monthly. This involves removing and cleaning the ice-making components, such as the evaporator, water trough, and distribution tubes. Use a manufacturer-approved cleaner and follow the instructions for safe and effective cleaning.

b. Sanitize the Ice Bin

Contact your service professional to sanitize the ice bin using a food-safe sanitizer. Ensure that all surfaces that come into contact with ice are thoroughly cleaned and sanitized to prevent bacterial growth. Rinse the bin with clean water and allow it to air dry before refilling it with ice.

4. Quarterly Maintenance

a. Clean the Condenser Coils

The condenser coils are critical for the efficient operation of the ice machine. Over time, these coils can become clogged with dust and debris, reducing the machine’s efficiency and increasing energy consumption. Contact your service professional to clean the coils quarterly using a soft brush or vacuum cleaner to remove any buildup.

b. Inspect and Clean the Water Lines

Check the water lines for any signs of mineral buildup or blockage. Hard water can cause scaling, which can restrict water flow and affect ice production. Use a descaling solution to clean the water lines and prevent mineral buildup.

5. Bi-Annual Maintenance

a. Professional Inspection and Maintenance

Schedule a professional inspection and maintenance service twice a year. A qualified technician can thoroughly inspect the machine, identify any potential issues, and perform necessary repairs or adjustments. This proactive approach can prevent costly breakdowns and extend the life of your ice machine.

b. Replace the Water Filter

Replace the water filter every six months to ensure the machine receives clean, uncontaminated water. This not only improves the quality of the ice but also helps protect the machine’s internal components from damage caused by impurities in the water.

Additional Tips

a. Monitor Ice Production

Keep an eye on the machine’s ice production levels. A noticeable decline in ice output can indicate underlying issues such as clogged filters, dirty components, or mechanical problems. Addressing these issues promptly can prevent further damage and restore efficient operation.

b. Maintain Proper Ventilation

Ensure that the ice machine has adequate ventilation. Proper airflow around the machine helps dissipate heat and prevents overheating, which can lead to mechanical failures. Keep the area around the machine free from obstructions and regularly clean the ventilation grilles.

c. Follow Manufacturer’s Guidelines

Always refer to the manufacturer’s guidelines for specific maintenance instructions and recommended cleaning products. Each ice machine model may have unique maintenance requirements, and adhering to these guidelines ensures optimal performance and longevity.

Regular maintenance of your ice machine is essential for ensuring a steady supply of clean, high-quality ice in your restaurant or foodservice establishment. By following this comprehensive checklist, you can keep your ice machine running efficiently, reduce the risk of breakdowns, and maintain a safe and sanitary environment. Investing time and effort in proper maintenance not only extends the life of your equipment but also contributes to the overall success of your business. Contact Joe Warren & Sons today to learn more.