In the heat of summer, your ice machine becomes one of the most valuable pieces of equipment in your kitchen. But if you haven’t given it the attention it deserves, it could be a hidden liability. Dirty or poorly maintained ice machines are notorious for mold growth, scale buildup, and surprise malfunctions—right when you need them the most.

Why Summer Ice Machine Problems Spike

The combination of heat and moisture creates the perfect environment for microbial growth inside your machine. When your demand for ice increases, so does the stress on the unit. Common issues include:

- Biofilm and mold buildup, which can contaminate ice and violate health codes.

- Scale deposits from hard water that clog internal components and reduce efficiency.

- Mechanical failure due to overuse or poor airflow in a hot kitchen.

Steps to Ensure Your Ice Machine Is Summer-Ready

- Schedule a Deep Cleaning A professional deep cleaning goes beyond a simple rinse. It includes disassembling key components, sanitizing the bin, evaporator and all internal components, flushing lines, and inspecting water filtration systems.

- Replace Water Filters Filters should be changed every 6 months—or sooner if your machine sees heavy use. A clogged filter reduces ice quality and production rate.

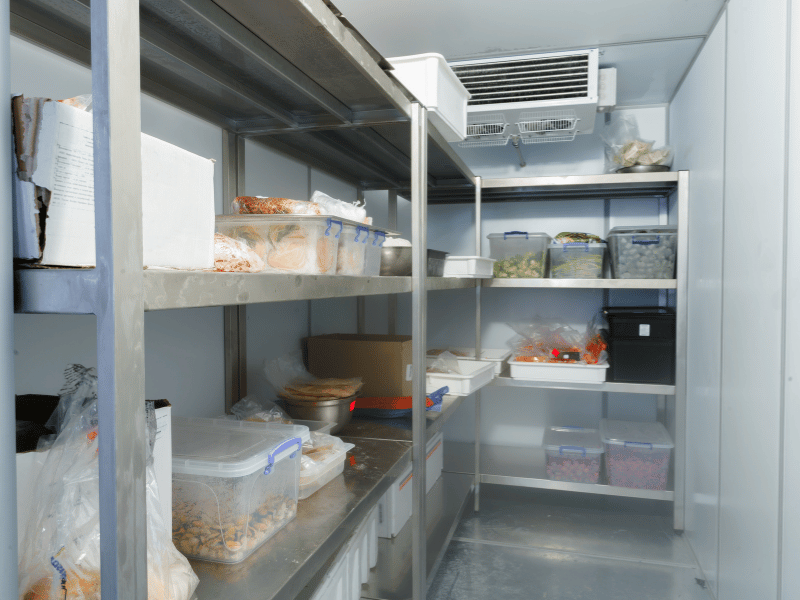

- Check for Airflow Issues Make sure your ice machine is in a well-ventilated area and that no boxes or supplies are blocking the intake or exhaust.

- Inspect the Bin for Mold or Odor The bin should be free of slime, mold, and odd smells. If you detect anything off, it’s a sign your machine needs a thorough cleaning.

- Test the Harvest Cycle Ensure the ice is releasing properly and that production time matches the manufacturer’s specs. If production is lagging, it could signal an underlying problem.

Stay Ahead of the Heat

Summer is too important to risk an ice machine breakdown. Let Joe Warren & Sons handle the dirty work—we’ll inspect, clean, and maintain your ice machine so it runs cool all season long. Contact us today.