For New England restaurants, hotels, and food service businesses, winter tends to bring a noticeable slowdown in foot traffic and demand. For companies that rely on commercial kitchens, this quieter season offers a unique opportunity to focus on planned maintenance, replacements, and upgrades. At Joe Warren & Sons, we believe that proactive equipment care during the winter months can help you stay prepared, efficient, and ready for the busy spring and summer seasons.

Here are some reasons why the off-peak winter period is ideal for servicing your commercial equipment:

1. Maximize Efficiency Before Peak Season Hits

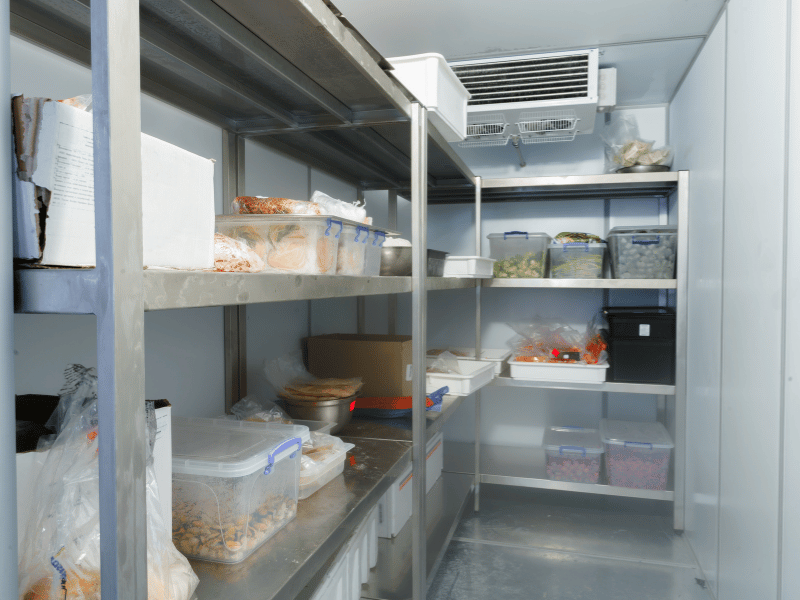

By scheduling maintenance during winter, businesses can ensure that their kitchen equipment is running at peak efficiency before the busy season returns. Taking time to inspect, clean, and repair equipment like refrigeration units, ovens, and dishwashers helps avoid last-minute breakdowns when business picks up.

Planned Maintenance Tip: Winter maintenance is the perfect time to check seals, clean coils, and perform a deep inspection to ensure optimal functionality. Well-maintained equipment runs more efficiently, saving energy and reducing operating costs.

2. Extend the Life of Your Equipment

Commercial kitchen equipment is a significant investment, and extending its lifespan is essential for maintaining a healthy bottom line. Regular maintenance prevents wear and tear and reduces the likelihood of needing costly replacements.

Maintenance Checklist: During off-peak times, have your equipment calibrated, inspect electrical connections, and check for signs of corrosion or stress. By addressing small issues early, you can prevent larger problems and prolong the life of your machines.

3. Increase Safety Standards

When kitchen equipment is overworked, it can lead to safety hazards that put your employees and customers at risk. Winter maintenance is an ideal time to conduct thorough inspections for any potential safety issues, such as malfunctioning thermostats or damaged electrical components, and replace or repair parts that could pose risks.

Winter Inspection Tasks: Have certified technicians inspect for gas leaks, faulty wiring, and any mechanical issues that may lead to accidents. Prioritizing safety through regular maintenance keeps your business compliant with local safety regulations.

4. Budget-Friendly Scheduling and Costs

Winter maintenance allows you to manage costs more effectively, as many service providers, including Joe Warren & Sons, offer flexible scheduling during the slower months. This flexibility means you can perform necessary maintenance and repairs without disrupting business operations or paying peak-season prices.

Cost Efficiency: Investing in off-peak maintenance can prevent emergency repairs and downtime costs, which are often much higher during the busy season. Proactive a.k.a. planned maintenance saves money and prepares your business for an uninterrupted service period.

5. Prepare for Upgrades and Innovations

Winter is a great time to assess whether your kitchen could benefit from upgrades or new equipment installations. The slower season offers time to research new technology and consider energy-efficient options that could improve performance and lower costs over the long term.

Upgrade Opportunity: Evaluate energy-efficient refrigeration units or cooking equipment with advanced features that align with your operational goals. Joe Warren & Sons’ team can help you plan and install new equipment with minimal disruption to your service schedule.

6. Take Advantage of Service Availability

Since winter is a slower season for many food service providers, service technicians have more availability. Booking maintenance during this period ensures that you’ll get the expert attention you need without long wait times, helping you get back to business as usual faster.

Winter may be a slower time for New England businesses, but it’s the perfect season for giving your commercial kitchen equipment the care it deserves. By scheduling preventive maintenance, servicing existing machines, and planning for potential upgrades, you set your business up for a smooth, efficient operation when the busy season returns.

If you’re ready to schedule your winter maintenance, reach out to Joe Warren & Sons today. Our expert technicians are here to keep your equipment in top shape, ensuring you stay compliant, efficient, and prepared for success year-round.