Ensuring the optimal performance of commercial food equipment is essential for any business in the food service industry. One often overlooked aspect of equipment care is the effect of changing seasons on performance and maintenance needs. In New England, the stark contrast between harsh winters and warm summer months presents unique challenges. This guide will provide seasonal maintenance tips to keep your commercial food equipment running smoothly throughout the year.

Surviving the Harsh Winters

Cold winters in New England can severely impact your food equipment’s performance. Here are some maintenance tasks to prioritize during these months:

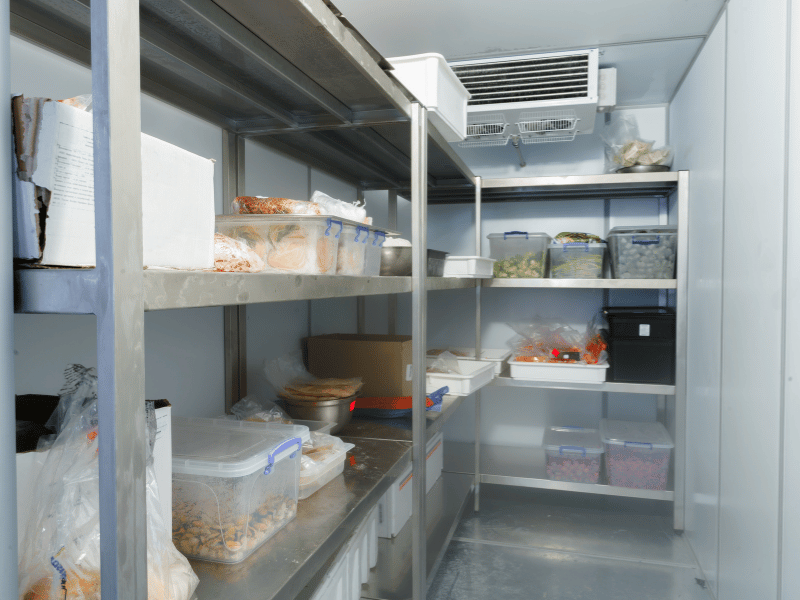

1. Check and Clean Refrigeration Units: As the ambient temperature drops, your refrigeration and freezer units may not have to work as hard to maintain their internal temperatures. Use this time to give them a thorough cleaning, removing any ice buildup that might have occurred during the warmer months. Check the seals for any damages to prevent cold air leakage.

2. Inspect Your Heating Equipment: Ovens, ranges, and fryers see heavy usage during winter, providing much-needed warmth in the kitchen. Ensure these units are clean and their components are in good working condition. Professional calibration of your ovens will ensure they provide accurate temperatures for perfect winter roasts.

3. Protect Water Lines: Water supply lines can freeze in the winter, potentially causing severe damage to your equipment. Insulate the water lines and routinely check for any sign of freezing.

Welcoming the Warm Months

As New England thaws out and welcomes the warmer months, your maintenance priorities should shift in response to the changing demands on your equipment.

1. Service Your Refrigeration Units: Higher ambient temperatures mean refrigeration and freezer units need to work harder to keep cool. Pre-empt any issues by servicing these units before the weather heats up. Regularly clean the condenser coils and check for any coolant leaks.

2. Deep Clean Your Grills: The arrival of warmer weather often increases demand for grilled foods. Deep clean your grills to remove any winter buildup and check for any wear and tear. Don’t forget to inspect your outdoor cooking equipment, if applicable.

3. Evaluate Your HVAC System: With temperatures rising, your kitchen’s HVAC system will be working overtime to keep the area comfortable. Schedule a professional inspection to ensure your HVAC system is ready to handle the heat.

4. Pest Control Measures: Warmer weather can also mean an increase in pests. Regularly clean and sanitize all food equipment and surrounding areas, taking care to remove any food debris that may attract unwanted visitors.

Embracing the Changing Seasons

By adjusting your maintenance routines to meet the demands of each season, you can keep your commercial food equipment in peak condition year-round. Regular maintenance reduces the risk of unexpected breakdowns, prolongs the life of your equipment, and helps maintain the high food quality your customers expect. As the seasons change in New England, so too should your approach to food equipment maintenance. The time invested in seasonal maintenance will pay dividends in the form of reliable, efficient equipment ready to meet the demands of any New England weather.