Installing a walk-in cooler in your restaurant’s kitchen is a significant investment that can enhance efficiency, storage capacity, and food safety. However, the installation process can be complex and require careful planning and execution. In this blog post, we’ll discuss what to expect during the walk-in cooler installation process, from initial planning to final inspection, to help you prepare for a seamless installation experience.

Site Assessment:

- The first step in the walk-in cooler installation process is a thorough site assessment conducted by experienced technicians. During this assessment, the technicians will evaluate the available space, electrical and plumbing connections, ventilation requirements, and any structural considerations that may impact the installation. This information will help determine the optimal location and size of the walk-in cooler and ensure compliance with building codes and regulations.

Design and Customization:

- Once the site assessment is complete, the next step is to design the walk-in cooler to meet your specific needs and requirements. This may include customizing the cooler’s dimensions, layout, shelving options, door configurations, and insulation levels. Our team of experts will work closely with you (and in some cases other channel partners) to create a tailored design that maximizes storage capacity, efficiency, and functionality while adhering to your budget and timeline.

Permitting and Approval:

- Before the installation can proceed, all necessary permits and approvals must be obtained from local authorities. We’ll work closely with your team(s) to expedite the approval process on our end and minimize delays, keeping your project on track.

Installation and Assembly:

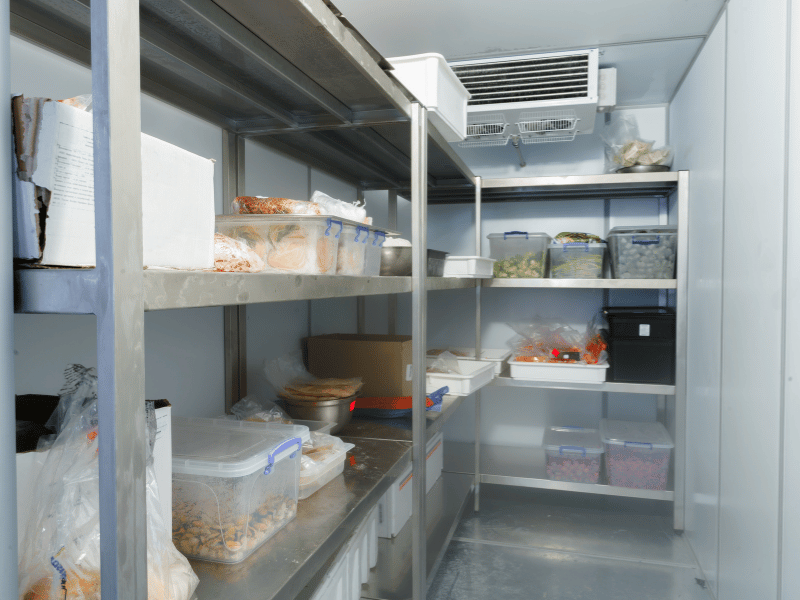

- With permits in hand, our skilled technicians will begin the installation and assembly of your walk-in cooler according to the approved design plan. This may involve constructing the cooler’s walls, installing insulation and flooring, assembling shelving units, and mounting refrigeration units and doors. Our team will work efficiently and meticulously to ensure the installation is completed to the highest standards of quality and craftsmanship.

Testing and Commissioning:

- Once the walk-in cooler is assembled, our technicians will conduct comprehensive testing and commissioning to ensure that all components are functioning correctly and meeting performance specifications. This may include testing temperature and humidity levels, checking for air leaks, verifying electrical and plumbing connections, and calibrating refrigeration units. We’ll also provide training to your staff on proper operation and maintenance procedures to ensure long-term reliability and performance.

Final Inspection and Handover:

- After testing and commissioning are complete, a final inspection will be conducted to verify that the walk-in cooler meets all regulatory requirements and industry standards. Once approved, we’ll hand over the completed installation to you, providing documentation and ongoing support to ensure your satisfaction and peace of mind.

Installing a walk-in cooler is a complex process that requires careful planning, expertise, and attention to detail. By partnering with a reputable commercial kitchen equipment installation and repair company like ours, you can expect a smooth and seamless installation experience from start to finish.

Contact us today to learn more about our walk-in cooler installation services and how we can help take your foodservice operation to the next level.